Rope Technology

The working field of the department of Rope Technology include Destructive Rope Testing, Non-Destructive Rope Testing and Ropes for Offshore Technology. Approvals and notifications exist for the areas of cableway technology and personal protective equipment in mountain sports (PPE).

Machine Design and Material Flow Automation

The department of Machine Design and Material Flow Automation generates innovative research ideas - both in research and development projects and in industrial projects - and deals with the development and optimization of new machines and components.

Logistics

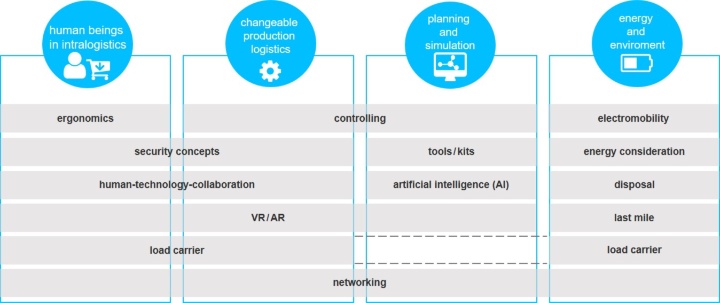

The field of expertise of the logistics department can be divided into four areas:

- The human being facto in intralogistics (especially in manual picking)

- Changeable production logistics (cross-departmental field of activity)

- Planning and simulation in intralogistics

- Energy and environment (electromobility, sustainable charge carriers, etc.)

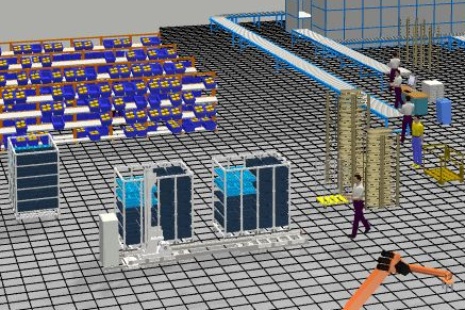

At the IFT three test stations can be used for research activities, industrial cooperations and teaching.

The VR room to investigate the possible use of virtual reality in intralogistics, the Learning Warehouse (LernLager) for the scientific analysis of manual picking processes and a RFID (radio-frequency identification) test station, where the conditions for the application of this technology in practice can be investigated.

New developments of the IFT in the field of flexible production logistics, for example in automobile production, are tested in ARENA2036 (Active Research Environment for the Next Generation of Automobiles).